THE CHALLENGE

Kraft Heinz, a global food and beverage manufacturer for retail and foodservice markets, required a robust on-premise paging system to strengthen safety and communication throughout its production facility in Kendallville, Indiana. The objective was to implement a scalable, wireless paging solution that could support routine daily voice announcements as well as real-time audio-visual emergency notifications. The food manufacturing paging system needed to ensure dependable, facility-wide coverage with the following core capabilities:

THE SOLUTION

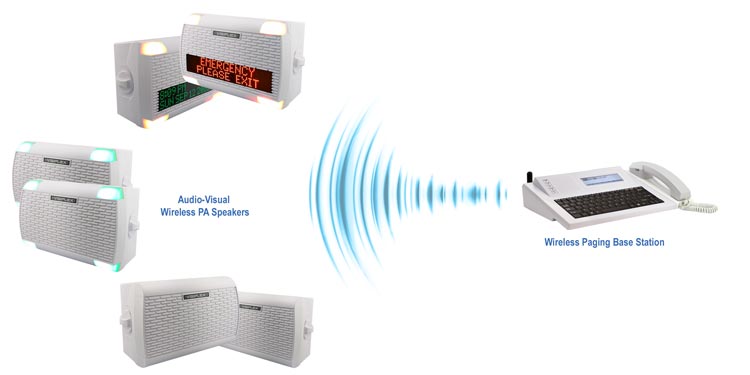

Visiplex’s wireless food manufacturing paging system was deployed using a centralized wireless paging base station located in the facility’s main office. The system included audio-visual wireless PA speakers strategically installed across the production floor and key safety areas—including break zones, smoking areas, muster points, and parking lots—to provide full facility-wide voice coverage in both indoor and outdoor environments.

To enhance visibility and ensure ADA compliance, the system also incorporated LED message boards and multi-color beacon lights, delivering clear, real-time visual alerts during emergency situations.

Facility-wide audio-visual alerts can be triggered directly from the base station or remotely via phone, allowing for quick, targeted responses to incidents such as equipment failure, chemical spills, or workplace injuries.

In addition to emergency use, the system supports daily operational communication—broadcasting live voice messages, shift change announcements, and scheduled break bell alerts. The integrated LED displays provide synchronized time and display important facility updates with high visibility across the manufacturing floor.

The Visiplex food manufacturing paging system was installed by certified technicians with minimal disruption to operations. Final system testing, commissioning, and on-site staff training were completed to ensure reliable performance and seamless integration into daily workflows.

THE RESULTS

Optimized Wireless Food Manufacturing Paging System – The fully integrated wireless audio-visual paging system was successfully deployed across Kraft Heinz food manufacturing facility, significantly improving site-wide safety, emergency preparedness, and real-time communication with staff and visitors. This scalable solution streamlined operations while delivering the following key capabilities:

Regulatory Compliance References

All copyrights belong to their respective owners. Images and text owned by other copyright holders are used here under the guidelines of the Fair Use provisions of United States Copyright Law.